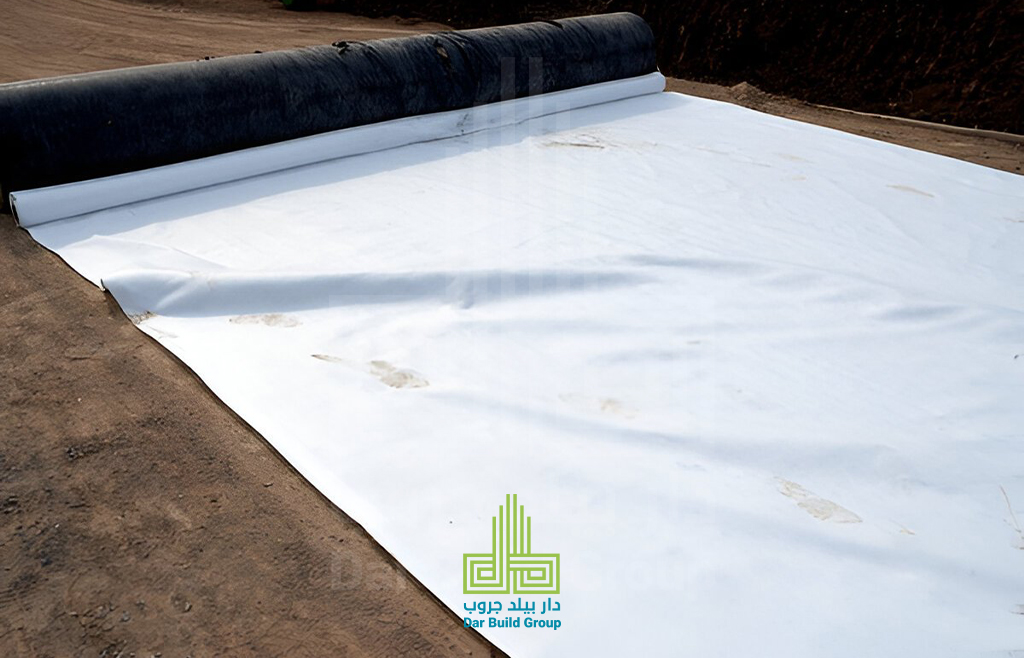

Geotextile

Polyester geotextile is a highly durable synthetic fabric used in construction and agricultural applications, characterized by its excellent tensile strength, tear resistance, and resistance to chemical agents.

Overview

Polyester geotextile is a modern material that plays a key role in infrastructure works and agricultural projects, combining high mechanical strength with durability against tearing and environmental factors.

Technical specifications

Available in various weights ranging from 100 to 1500 g/m² depending on the application.

Features high tensile strength and excellent resistance to tearing and pressure.

Allows water permeability while maintaining soil stability and preventing layer mixing.

Resistant to acids, alkalis, and most chemicals present in the soil.

Withstands high temperatures without losing its properties.

Long-lasting and resistant to ultraviolet (UV) radiation and environmental degradation.

Areas of use

Used to reinforce ground layers and prevent soil mixing, which improves stability and durability.

Acts as an effective filter that allows water to pass smoothly while preventing drainage system clogging.

Contributes to preventing soil erosion and helps distribute water evenly in agricultural projects.

Used as a protection and separation layer that prevents leakage and maintains the integrity of concrete structures and dams.

Provides additional insulation and protection for membrane layers in environmental lining and landfill projects.

Increases the soil's bearing capacity and limits settlement caused by heavy loads in roads and railways.

How to use and apply

1. Site Preparation

Clean the ground of stones and debris.

Level the surface to ensure even distribution of the geotextile.

2. Laying the Geotextile

Spread it directly on the ground or between soil layers.

Consider the fiber orientation based on the geotextile type (Uniaxial or Biaxial).

3. Anchoring and Fastening

Secure using ground staples or specialized nails.

Maintain an overlap between strips (usually 30 to 50 cm) to prevent sliding.

4. Adding Subsequent Layers

Cover with a layer of sand, gravel, or soil depending on the project type.

In roads, place the base course or asphalt layer directly over it.

5. Final Inspection

Ensure there are no tears or folds.

Verify even distribution and proper fastening.

Product features

High Tensile Strength: Provides excellent load-bearing capacity for heavy-duty applications.

Corrosion and Chemical Resistance: Makes it suitable for use in harsh and demanding environments.

Effective Filtration: Allows water permeability while preventing the passage of solid particles, acting as an efficient filter.

Soil Stability: Reduces soil settlement and maintains the stability of ground layers.

Long Service Life: Features a long life span and high resistance to ultraviolet (UV) radiation.

Lightweight and Easy to Install: Reduces installation time and effort at various project sites.

Storage and shelf life

Polyester geotextile is available in rolls of various sizes and lengths

with different densities to suit the needs of construction and agricultural projects.

Product unit

Product Unit of Measurement: Our Geotextile products are sold by the Square Meter ($m^2$) to ensure precise calculations for your engineering requirements. The product is available in various weights and densities ranging from 100 to 1500 g/m². For convenience in transport and installation, it is supplied in standard Rolls, with widths and lengths customizable based on your specific project technical specifications.