Geogrid

Geogrid is a mesh made of high-strength polymers such as polyester or high-density polyethylene (HDPE), available in rolls that are laid between layers of soil or asphalt.

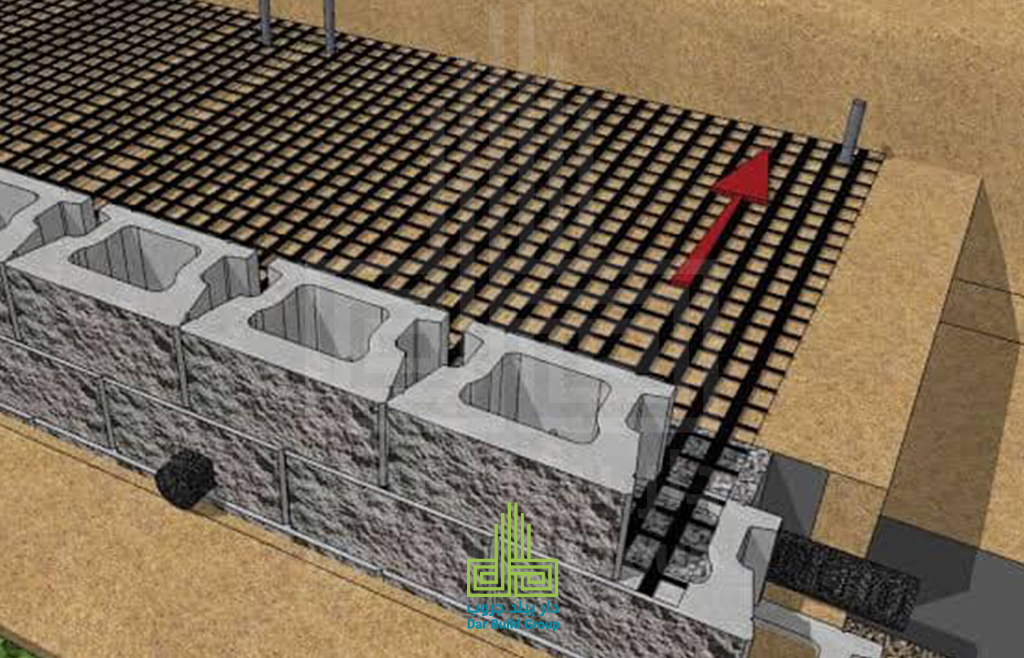

Its open-mesh structure allows soil particles to interlock with the mesh, enhancing soil strength and stability.

Overview

• HDPE (High-Density Polyethylene): Tear and puncture resistant, used for ground insulation and roofing.

• LDPE (Low-Density Polyethylene): More flexible, used in light applications such as covering materials or as a substrate under tiles and concrete.

Technical specifications

High-performance geogrids manufactured from ultra-durable polymeric materials, designed specifically for soil reinforcement and strengthening base layers in road, railway, and retaining wall projects.

They are characterized by high tensile strength and a high modulus of elasticity that ensures ideal distribution of vertical loads and their conversion into lateral pressures, which prevents structural settlement and reduces the required pavement layer thickness. They also enjoy full resistance to chemical and biological factors in the soil and ultraviolet (UV) radiation.

They are manufactured according to the highest international standards, such as (ASTM D6637), to provide superior mechanical stability and ideal interlocking with aggregate, making them the perfect solution for increasing the efficiency of structures and ensuring their sustainability under maximum operating conditions.

Areas of use

The fields of application for our products vary to include vital construction sectors, as they are used in infrastructure projects, road construction, and railways to strengthen base layers and stabilize weak soil.

And in residential and commercial projects to provide integrated waterproofing, thermal, and acoustic insulation systems for roofs, foundations, and bathrooms.

In addition to applications for industrial facilities, airports, and ports that require materials with high resistance to heavy loads.

Our solutions are also essential in the restoration and reinforcement of concrete structures and the protection of retaining walls and slopes from collapse, leading to the equipping of swimming pools and water reservoirs with certified materials that ensure the highest levels of safety and sustainability against leakage and environmental factors.

How to use and apply

1. Site Preparation

Clean the ground from any impurities or construction waste.

Level the soil thoroughly to ensure a flat surface before spreading the geogrid.

Ensure the ground is dry if applied over an insulation layer.

2. Spreading the Geogrid

Spread the geogrid directly onto the soil, insulation layer, or concrete, depending on the application.

Fiber orientation must align with the direction of loads or expected expansion.

In case of using multiple strips, an overlap of 30–50 cm is required, depending on the geogrid type.

3. Anchoring and Fastening

Secure the geogrid using ground staples (U-Pins) or specialized fastening nails.

Fastening should be done every 1.5 to 2 meters, both longitudinally and transversally, to ensure complete stability.

In areas exposed to wind or movement, additional fastening at the edges and corners is preferred.

4. Upper Layers

After fastening, place the protection layer, backfill, or concrete directly over the geogrid.

If used as a base for tiles or interlocking stones, cover it with a layer of clean sand before paving.

Product Features

High Tensile Strength: It features a superior ability to withstand large vertical loads and distribute them efficiently.

Long Service Life: Manufactured from polymeric materials resistant to corrosion and environmental factors to ensure sustainability.

Chemical and Biological Resistance: It enjoys full resistance to acids and alkalis present in the soil and is not affected by bacteria.

Cost-Effective: It reduces the required thickness of pavement layers and saves on the quantities of aggregate used.

Superior Mechanical Stability: Provides perfect interlocking with soil particles and aggregate to prevent sliding or settlement.

UV Resistance: Designed to withstand exposure to direct sunlight during the installation process without losing its properties.

Compliance with Global Standards: Manufactured according to the American Society for Testing and Materials specifications (ASTM D6637).

Storage and shelf life

Storage Environment: Geogrid rolls must be stored in a dry and clean place away from direct moisture and dust to ensure the fibers remain clean and facilitate interlocking with the soil.

Sun Protection: Despite its resistance to ultraviolet (UV) radiation, it is preferable to cover it or store it in a shaded area if the storage period is long to avoid continuous and direct exposure to strong sunlight.

Proper Positioning: Rolls should be stored horizontally on a level surface to prevent deformation of the grid structure or curling at the edges.

Product unit

It varies depending on the manufacturer, but is typically (2 to 4 meters) in width and (50 to 100 meters) in length